Got Questions?

Find answers to questions we always receive. If your query is not there, send us a message! We’re here to help.

General

Who is PVinsight?

PVinsight is a spin-out company of Nelson Mandela University. It is a company dedicated to the laboratory and on-site testing and inspection of photovoltaic (PV) modules, providing data-driven analysis to ensure optimal performance and reliability of solar power systems.

The PV testing lab was established in 2014 to meet the need for testing in the South African PV industry.

For more information about PVinsight visit: https://www.pvinsight.co.za/about-us/

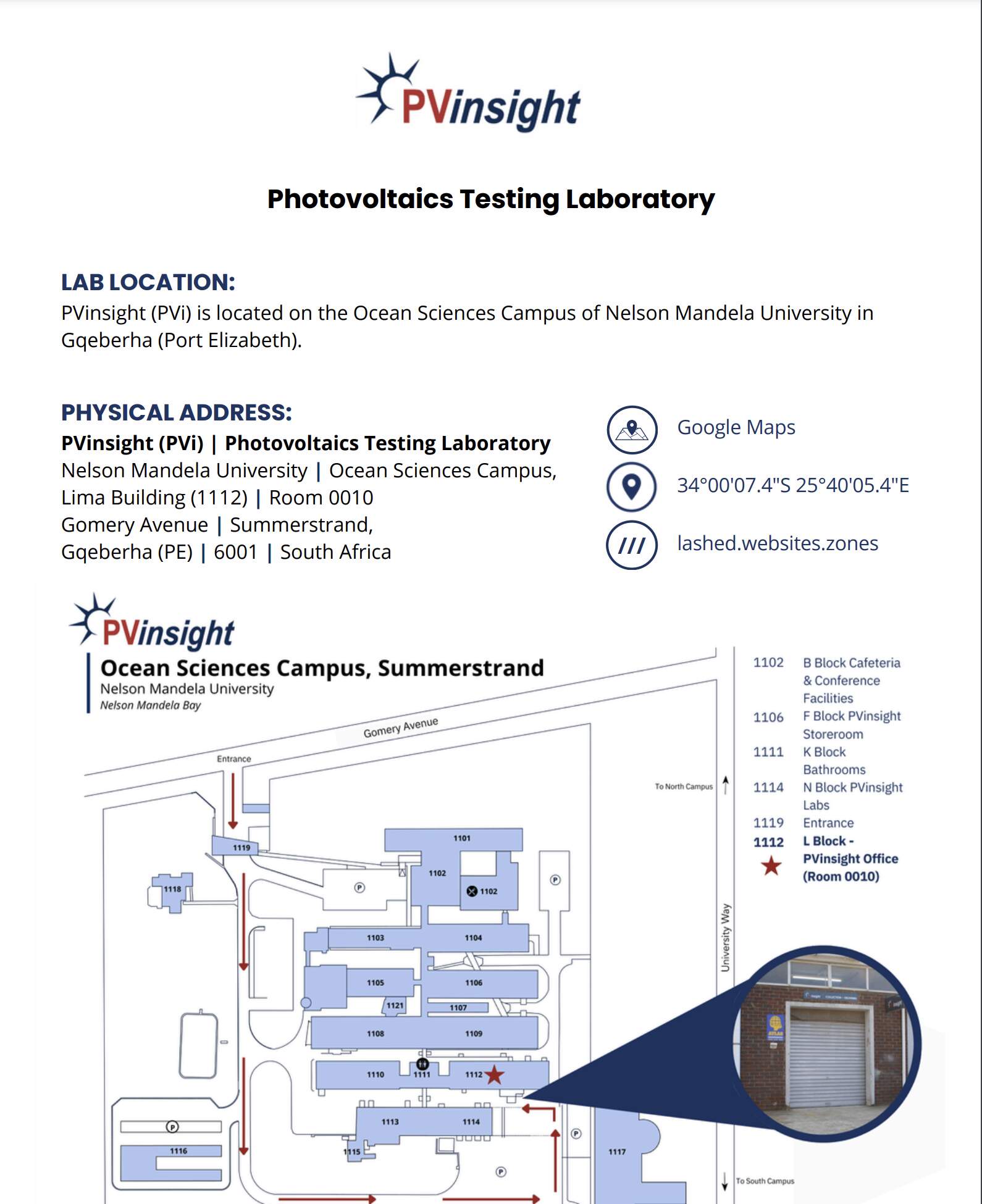

Where are you based?

What are your office hours?

Our regular office hours are 08:30 AM to 04:00 PM, Monday to Friday. However, you can email us at info@pvinsight.co.za or submit enquiries through our website at any time.

How can I contact you?

Visit our Contact Us page on our website or email us at info@pvinsight.co.za.

Are the tests performed by PVinsight accredited?

PVinsight is accredited with South African National Accreditation System (SANAS) for ISO 17025:2017. In additional to our accredited tests, we also offer additional non- accredited tests according to our validated in-house procedures. Our scope of Accreditation is available at https://www.pvinsight.co.za/wp-content/uploads/2025/03/PVinsight_T0956-Certificate-of-Accreditation-02.pdf

What Testing services does PVinsight offer?

For more information about our Testing Services visit: https://www.pvinsight.co.za/services/

Testing Information

Why is it important to test the quality of PV modules?

Ensures Performance & Efficiency

- Modules must generate the expected power output under real-world conditions.

- IV curve tracing helps confirm electrical characteristics match design specifications.

- Performance degradation can occur due to microcracks, potential-induced degradation (PID), or manufacturing inconsistencies.

Detects Hidden Defects & Manufacturing Issues

Even new modules can have hidden defects from production, handling, or transport:

- Microcracks – Reduce power output over time.

- Hotspots – Can cause overheating and permanent damage.

- Soldering Issues – Affect internal connections, leading to failures.

- Glass or Encapsulation Defects – Cause moisture ingress, corrosion, or delamination.

Prevents Early Degradation & Warranty Claims

- Quality issues may lead to rapid degradation, reducing system lifespan.

- Early testing helps identify problems within warranty periods, allowing for timely claims and module replacements.

Improves Safety & Reduces Fire Risk

- Faulty modules can lead to electrical hazards, such as insulation breakdown and arc faults.

- Insulation resistance (IR) testing ensures modules meet safety standards.

- Thermal imaging detects overheating components that could cause fires.

Ensures Compliance with Standards & Contracts

- Third-party testing verifies compliance with IEC standards (e.g., IEC 61215, IEC 61730).

- For large-scale projects, independent quality control is often required to meet contract terms and financial guarantees.

Are a PV Module and a Solar Panel the same thing?

Yes, while it is commonly referred to as a Solar Panel, a Photovoltaics module or PV module is the same thing.

How do I pack and prepare my PV modules for testing?

To prepare your PV modules for testing, ensure they are clean and free from debris. If you are transporting the modules to our lab, please pack them securely to prevent any damage during transit. This means that they should ideally be packed vertically in a crate. Crating solutions and advice are available on request. An example of module packing is provided below.

Is it possible to test PV module with broken glass?

No, we are not able to test PV modules with broken glass. PV modules with broken glass cannot be safely used or repaired so the best option is to recycle them through a registered e-Waste recycler.

How can PV modules be disposed of?

According to National Norms & Standards for Disposal of Waste to Landfill of 2013, PV modules are classified as e-Waste and cannot be sent to landfill. They must be recycled by a registered e-Waste recycler.

For more information on the EPR regulations refer to the National Environmental Management Act: Waste Act (59 of 2008), which took effect on the 5th of November 2021.

What types of PV modules can be tested at PVinsight?

We test a variety of photovoltaic modules, including single-crystalline silicon, polycrystalline silicon, thin-film, and bifacial modules. Our testing protocols are designed to accommodate the specific characteristics of each module type.

Sales Enquiries, Pricing and Quotes

What is the cost of testing?

The cost of testing varies depending on the type and scope of the testing required. Please contact us with details about your testing needs to decide what tests are appropriate for you and we will provide you with a customised quote.

How can I request a quote for your services?

To request a quote, please complete online form on our website or email us at info@pvinsight.co.za.

Do you offer discounts for long-term contracts or large volume testing?

Yes, we have special discounts available for long-term contracts and for large volume testing. Please email us at info@pvinsight.co.za for more information.

What information is required for a quote?

To ensure an accurate quote, please provide the following details:

- Plant/ System size

- PV Plant Location

- System Configuration (layout and key specifications) for On-site tests

- Reason for testing (concerns or specific requirements)

- Contractual obligation (Are you obligated to test based on contract? Please provide exact wording and required criteria or standards.)

- If testing is due to early failures or performance degradation, we recommend a discussion around concerns with one of our experts to determine the best approach.

Our Services

What services does PVI offer?

For more information about our Testing Services visit: https://www.pvinsight.co.za/services/

Can PVinsight assist with testing residential or C&I roof top systems? – How can I check the performance of my roof-top PV system?

Yes, if you have concerns about your rooftop or C&I System that are related to the PV modules then PVinsight can assist. If there are concerns about the electrical system configuration, inverter or batteries it is better to consult with a registered Electrician.

The current- voltage measurements of the strings can be measured to ensure that the modules are performing as expected and it is possible to perform further testing like EL and Visual inspection.

For more information about our Residential – Roof Installation Use Case- Visit: https://www.pvinsight.co.za/services/

There has been an extreme weather event (hailstorm or high winds etc), how can I check for damage in my PV system?

After the event, there might be some modules with broken glass, or the modules could all have survived without the glass breaking. Modules with broken glass should be removed and replaced. The only way to determine the full extent of the damage it to do an EL test to detect any invisible cracks that might have occurred in the cells.

For more information about our C&I- Roof Installation Use Case- Visit: https://www.pvinsight.co.za/services/

I have concerns about how my PV modules were handled during installation. The installers walked over them in order to complete the installation. Is it possible that the modules were damaged?

Yes, this module handling could cause micro cracks which are invisible cracks in the cells. These can be detected using EL imaging. It is important to note that not all Microcracks are not critical but it is important to identify them and assign a root cause as soon as possible so that they can support any future claims.

For more information about our Post-Installation Testing Use Case- Visit: https://www.pvinsight.co.za/services/

My modules are certified by the manufacturer, do I still need to test them?

Certifications (e.g., IEC 61215, IEC 61730) confirm modules meet industry standards under controlled laboratory conditions, not necessarily real-world conditions. Additional testing will also confirm the quality of the PV module and ensure that the Power output is as specified. Some warranties require initial and periodic testing to validate claims.

For more information about our Post-Shipment Testing Use Case- Visit: https://www.pvinsight.co.za/services/

How are the Mobile Lab testing service different from the lab testing services?

PVinsight can offer fully accredited testing service both at the Lab based in Gqeberha and at on-site locations such as the PV Plant.

The MBJ Mobile Lab 5.0 is a fully integrated PV test centre that can perform the Power and EL Measurements in a Trailer. Allowing these tests to be completed anywhere in South Africa.

The choice between these approaches depends on the specific requirements of the project include time frame and costs.

Glint and Glare

When does my project need a Glint and Glare Assessment?

SACAA Regulations and Technical Standards (CARS and CATS) often require Aeronautical Studies for developments deemed to present high safety and/or operational risk to nearby aerodromes, or in an urban area.

What is involved in a Glint and Glare Assessment?

The is a desktop study that involves the assessment of the potential reflective impacts of solar photovoltaic (PV) installations, buildings, or other reflective surfaces on nearby infrastructure, such as roads, airports, and residential areas.

The location of the PV plant with the details of the system is used to determine the Risks of Glare at set observation points which can include flight paths and airport decent routes. The Glare hazard is classified and mitigation measures can be suggested.

For more information about our Glint and Glare Services visit: https://www.pvinsight.co.za/services/

Recruitment

Are you hiring?

How can I apply for a job at your company?

We periodically post job openings on our Careers page which will include the application process.